Shot Blasting Equipment in Aerospace Industry

Shot Blasting Equipment explained with aerospace surface treatment and finishing

In the aerospace industry, precision and reliability are of utmost importance. Shot blasting equipment plays a vital role in aerospace surface treatment,aerospace surface finishing and aerospace shot peening, providing an efficient method for cleaning and roughening aircraft components. Roster aerospace surface treatment,aerospace surface finishing and aerospace shot peening, ensure enhanced bonding for coatings, structural integrity, and above all, safety in aviation. The high standards of the aerospace industry necessitate the use of such advanced surface preparation techniques to maintain the quality and performance of aircraft.

Aerospace surface treatment and finishing applications

Shot blasting is used extensively in the aerospace industry, with Roster aerospace surface treatment,aerospace surface finishing and aerospace shot peening, finding application in various areas. It is used on landing gear, where it helps remove old paint and rust, preparing the surface for new coatings. It is also used on aircraft surfaces, where it ensures a clean and rough surface for better adhesion of paints and coatings. Engine components also benefit from shot blasting, as it aids in the removal of carbon deposits and other residues, ensuring optimal performance.

Aerospace surface treatment and finishing Effects

The use of shot blasting in the aerospace industry has significant effects. It results in improved safety by ensuring that all components are clean and free from potential failure points like rust or old paint. Roster aerospace surface treatment,aerospace surface finishing and aerospace shot peening also enhance corrosion resistance, a critical factor given the harsh operating conditions of aircraft. Furthermore, it contributes to the longevity of aircraft components by providing a clean, rough surface that allows for better adhesion of protective coatings. These factors are paramount in aviation, making shot blasting an essential process in the industry.

Aerospace shot peening for various aircrafts components

Roster aerospace surface treatment supplier stands as a paragon in the aerospace industry, delivering unparalleled shot peening solutions for a myriad of critical components across various aircraft models. From high and low-pressure blades to bladed discs and impellers, our expertise spans a diverse spectrum of intricate aerospace machinery.

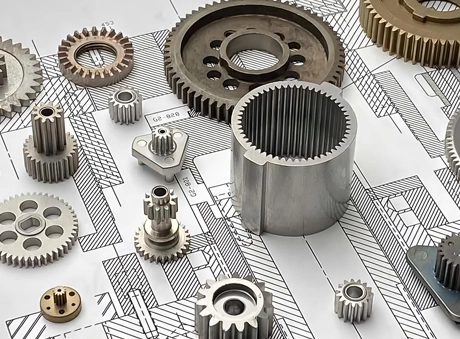

High and low-pressure blades, including foot, fan blades, airfoils, and fan blade root fixations, undergo meticulous shot peening processes to enhance their fatigue resistance and structural integrity. Bladed discs, also known as IBRs, DAMs, or BLISKs, receive the same meticulous treatment, ensuring optimal performance under extreme conditions.

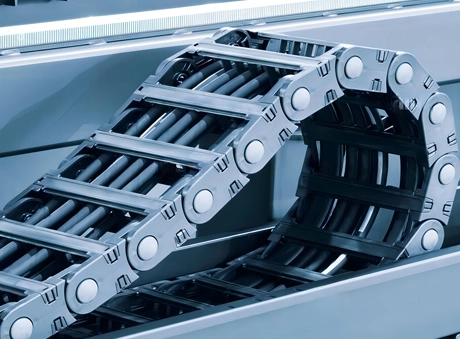

Portable shot peening equipment finds extensive use in various applications, including structural aluminum parts, wing/fuselage linkages, landing systems, cockpit windshields, and cabin window frames. Additionally, gears, auxiliary engines, wheels, brakes, and ball bearings benefit from our meticulous shot peening processes, guaranteeing unmatched performance and reliability.

At Roster aerospace surface treatment supplier, our commitment to excellence drives us to push the boundaries of innovation, ensuring that every component we treat meets the highest standards of quality and reliability. With our expertise and cutting-edge technologies, we continue to redefine the possibilities in aerospace engineering, ensuring safer and more efficient flights for generations to come.

Types of Shot Blasting Machines for Aerospace

Steel Plate Shot Blasting Machine, cylinder shot blasting machine, Floor Shot Blaster

Types of Sand Blasting Machines for Aerospace

High-pressure Air sandblasting machine, vacuum sand blasting machine, sand blasting room, sandblasting tank.

English

English