Features of Steel Cylinder Shot Blasting Machine

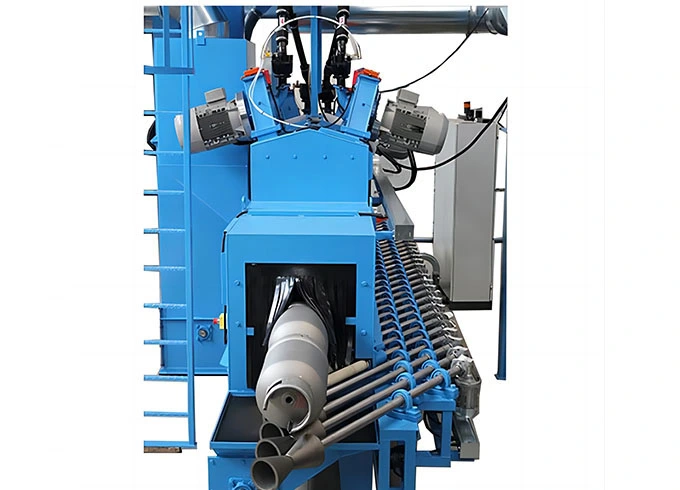

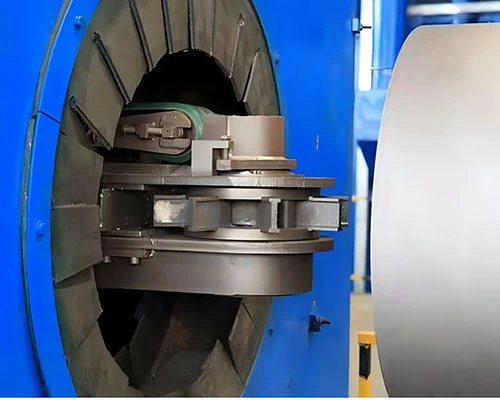

Adjustable blasting parameters for precise cleaning.

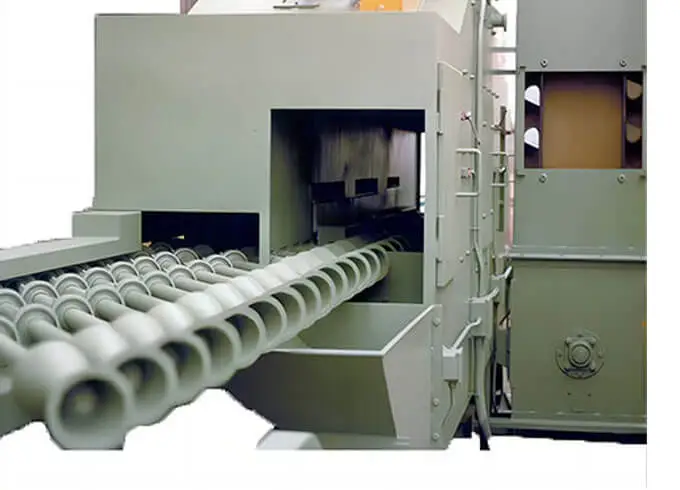

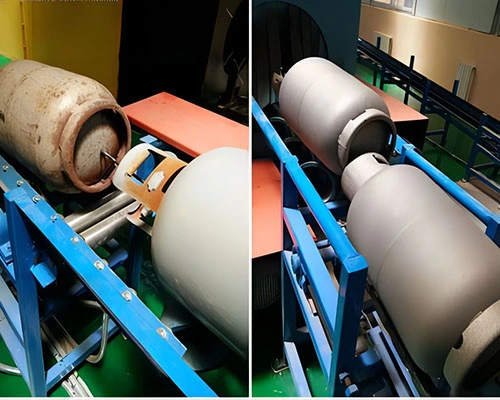

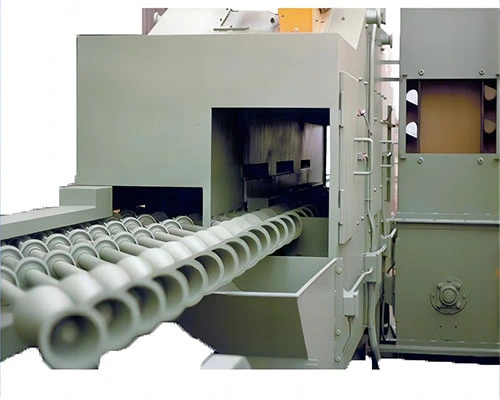

Efficiently handles varying sizes of steel cylinders.

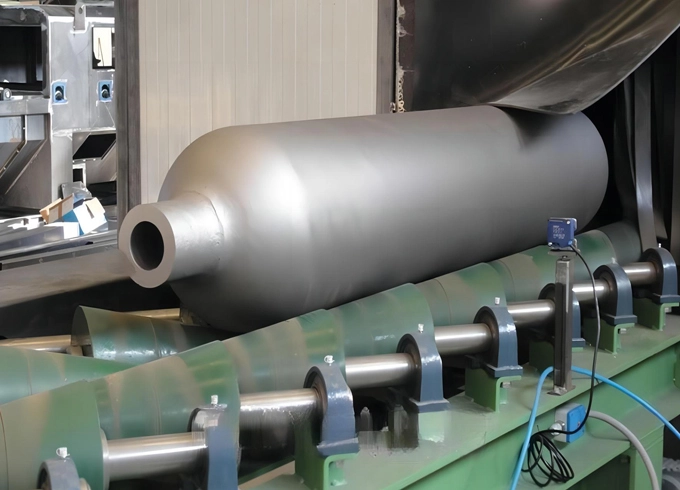

Ensures thorough and uniform surface preparation.

Designed for cleaning and preparing gas cylinders.

Efficient shot blasting of the interior and exterior ensures thorough abrasive blast cleaning.

Safety features for handling pressurized cylinders.

Benefits of Steel Cylinder Shot Blasting Machine

Enhanced gas cylinder integrity and safety.

Compliance with industry standards and regulations.

Improved surface finish for coating or painting, suitable for surface treatment in construction.

Cylinder shot blasting machine solutions in Gas and LPG

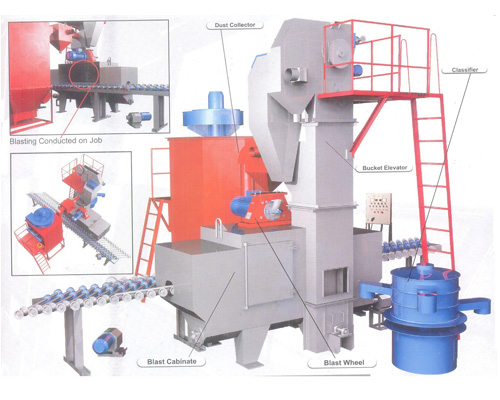

Companies in the gas and LPG (Liquefied Petroleum Gas) sectors require specialized cylinder shot blasting machines designed to handle the unique challenges of their industry. These industries work with hazardous, flammable materials, necessitating shot blasting equipment with robust safety features and explosion-proof construction.

Automatic cylinder shot blasting machines for gas and oil applications are engineered to accommodate the specific shapes and sizes of cylinders, tanks, and other equipment encountered in these industries.

These specialized cylinder shot blasting machines offer key features essential for the gas and LPG sectors. Cylinder shot blasting machines include explosion-proof designs for safe operation in potentially hazardous environments, automated loading and unloading mechanisms for efficient handling, precise part positioning and rotation capabilities ensuring even surface coverage, integrated dust collection and filtration systems for a clean work environment, advanced process control and monitoring features, and compliance with industry safety standards.

By utilizing these tailored cylinder shot blasting machines, gas and LPG companies can effectively prepare surfaces, remove contaminants, and improve coating adhesion on their critical equipment. The specialized design and safety features of these shot blasting solutions help gas and LPG operations maintain high standards of quality and compliance.

English

English