Benefits of Sand Blasting Room, Sand Blasting Booth for Sale

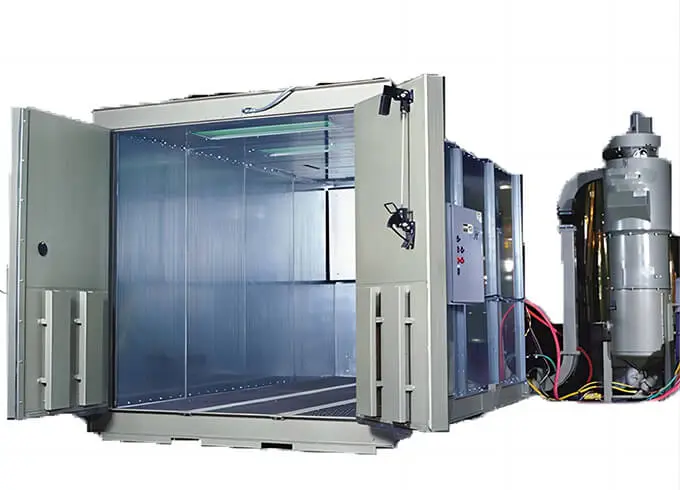

Enclosed sandblasting environment for large parts.

Customizable size, lighting, and ventilation options.

Dust extraction and media recycling systems.

Safe and controlled sandblasting for oversized components.

Customized solutions for specific applications.

Efficient and environmentally friendly operation.

Shipping container sandblast room uses

Shipping container sandblast rooms offer a portable and versatile solution for on-site surface preparation needs. These modified containers provide a controlled environment for abrasive blasting operations, protecting surrounding areas from dust and debris. These surface preparation equipment are ideal for temporary or remote projects where access to traditional sandblasting facilities is limited. Shipping container sandblast rooms can be easily transported and set up at various locations, making sand blasting booths for sale suitable for surface treatment in construction, shipyards, and industrial facilities. Sandblasting room for sale offers efficient containment of abrasive media and provide a safe working environment for operators, ensuring quality surface preparation results regardless of location.

Container sandblasting room

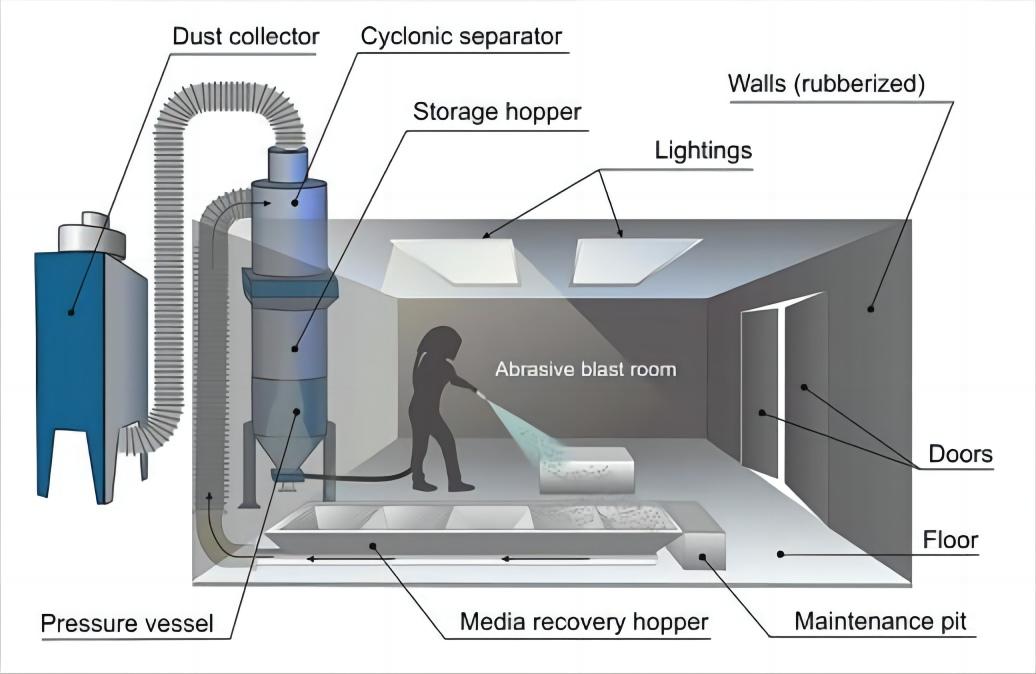

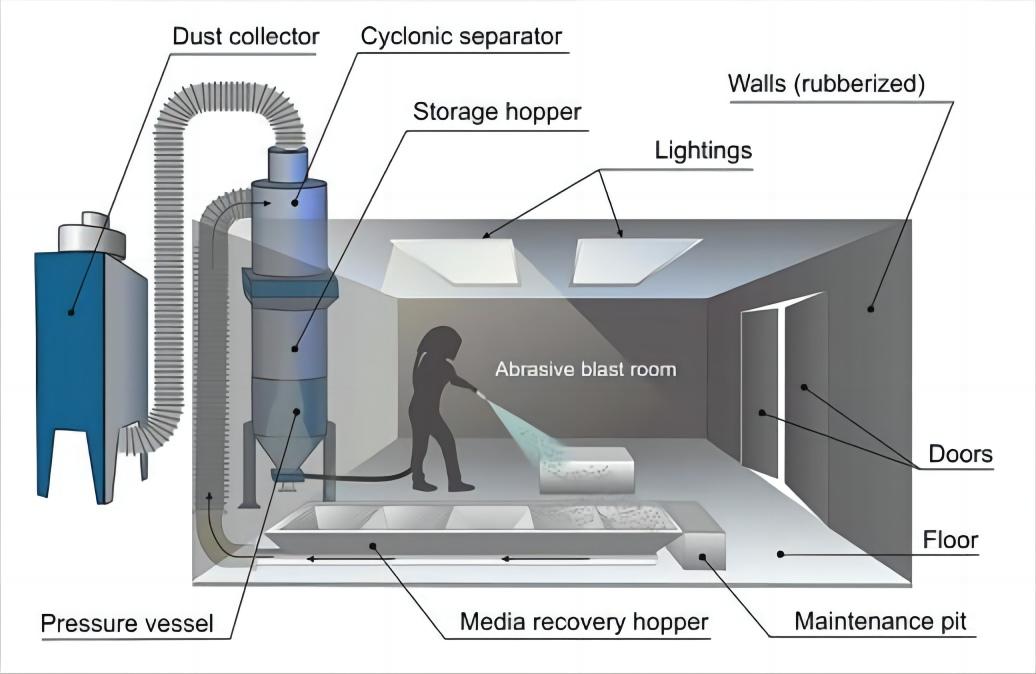

A container sandblasting room is a specialized enclosed space designed for sandblasting, a surface preparation technique that utilizes pressurized air and abrasive media like sand to clean and smooth various materials.

Surface Preparation: This involves cleaning and removing rust, paint, scale, or other contaminants from metal surfaces before painting, coating, or further processing. The container sandblasting room aims to create a uniform, roughened texture to prepare surfaces for new finishes. The container sandblasting room also facilitates surface preparation for welding, brazing, or other joining processes.

Restoration and Renovation: The container sandblasting room is used for stripping old paint, coatings, or finishes from items such as antique furniture, machinery, or architectural elements to restore their original appearance. This process involves removing dirt, grime, and oxidation to reveal the authentic features of historical or collectible items.

Industrial Applications: It's essential for deburring and descaling metal parts, castings, and forgings, as well as for etching or frosting glass, plastics, or other non-metallic surfaces. The container sandblasting room prepares surfaces for powder coating or other specialized coatings and removes contaminants from industrial equipment such as tanks, valves, and pipelines.

Art and Crafts: Artists and craftsmen use the room to create unique textures and finishes on artworks, sculptures, or custom-made products. The container sandblasting room is also suitable for etching designs or patterns on glass, ceramic, or stone surfaces and for distressing or aging materials for artistic or decorative purposes.

The controlled environment of a container sandblasting room ensures precise control over the sandblasting process, resulting in consistent outcomes while minimizing the risk of damage to the workpiece. Furthermore, the container sandblasting room effectively contains abrasive media and dust, enhancing efficiency and operator safety.

Shipping container sandblast room

Shipping container sandblast rooms have become a popular and versatile solution for various sandblasting applications.

Portable Sandblasting: Shipping container sandblast rooms can be easily transported and set up on-site, making them ideal for mobile or temporary sandblasting operations. This allows for sandblasting work to be performed at remote locations, construction sites, or anywhere a traditional sandblasting booth is not feasible.

Small-Scale Sandblasting: Shipping container sandblast rooms provide a contained and controlled environment for small-to-medium-sized sandblasting projects. Shipping container sandblast rooms are well-suited for sandblasting smaller parts, components, or items that do not require a large-scale industrial sandblasting facility.

Restoration and Refinishing: Shipping container sandblast rooms are often used in the restoration of antique furniture, architectural elements, or vintage machinery. The controlled environment allows for precise surface preparation while minimizing the risk of damage to delicate or fragile items.

Surface Preparation: Shipping container sandblast rooms can be used for preparing various surfaces, such as metal, wood, or concrete, prior to painting, coating, or further processing. This includes removing rust, old paint, or other contaminants to create a clean, uniform surface for the application of new finishes.

Specialized Sandblasting: Shipping container sandblast rooms can be customized to accommodate specific sandblasting requirements, such as the use of specialized abrasive media or the need for complex part handling.This makes them suitable for a wide range of industrial, automotive, or aerospace applications that require precise surface preparation.

Controlled Environment: The enclosed nature of a shipping container sandblast room helps to contain the abrasive media, dust, and debris generated during the sandblasting process. This creates a safer and more efficient working environment, particularly in areas with limited space or where environmental concerns are a factor.

The modularity, portability, and customizability of shipping container sandblast rooms make them a versatile and practical solution for a variety of sandblasting needs, from small-scale restoration projects to larger-scale industrial applications.

Abrasive blasting room engineered for all media blasting

Abrasive Blasting Room: An abrasive blasting room is a fully enclosed workspace specifically designed for conducting abrasive blasting operations. These abrasive blasting rooms are engineered to handle a variety of shot blasting machine spare parts, such as sand, steel shot, glass beads, and aluminum oxide. Key features include robust construction to withstand the abrasive impact, efficient dust collection systems for air quality control, specialized lighting and ventilation for safe operation, and adjustable blast nozzle positioning for optimal coverage. Abrasive blasting rooms ensure consistent, high-quality surface preparation across different materials and part sizes, making abrasive blasting rooms essential in industries like manufacturing, automotive, aerospace, and restoration.

Media Blasting Room: Media blasting rooms are tailored to accommodate specific blasting media requirements, including particle size, hardness, and cleaning capabilities. Media blasting rooms cater to diverse media such as glass beads, plastic media, and walnut shells, optimizing their effectiveness in various surface preparation tasks.

Grit Blasting Booth: A grit blasting booth is a smaller-scale abrasive blasting enclosure suitable for targeted operations on parts, components, or small objects. Featuring transparent viewing panels and ergonomic access points, these grit blasting booths provide a contained workspace for spot cleaning, finishing work, or localized surface preparation tasks.

Across these different types of blasting enclosures, the primary objectives remain consistent: providing a controlled environment, ensuring operator safety, and achieving uniform, high-quality results using specialized abrasive media and techniques.

Choose sandblasting room for sale

When considering a Roster sandblasting room for sale, you're opting for quality, reliability, and efficiency in surface preparation solutions. Roster's sandblasting room for sale is designed with precision and expertise to meet diverse industrial needs.

Cutting-edge Technology: As a shot blasting machine supplier, Roster integrates advanced technology into their sandblasting room for sale, ensuring optimal performance and consistent results in surface preparation applications.

Customization Options: With Roster, you have the flexibility to customize your sandblasting room for sale according to your specific requirements, whether it's size, configuration, or special features like dust collection systems or lighting.

Durability and Longevity: Roster sandblasting rooms for sale and industrial sand blasting equipment are constructed from high-quality materials, engineered for durability and longevity even under demanding operating conditions such as sandblast cylinder.

Comprehensive Support: Roster provides comprehensive support, including installation, training, and maintenance services, ensuring smooth operation and maximum uptime for your sandblasting room for sale.

Environmental Considerations: Roster prioritizes environmental sustainability by offering options for efficient dust collection and waste management systems, minimizing environmental impact while maximizing productivity.

With Roster sandblasting room for sale and a quality steel structure shot blasting machine, you're investing in a solution that delivers exceptional performance, reliability, and value for your surface preparation needs.

English

English