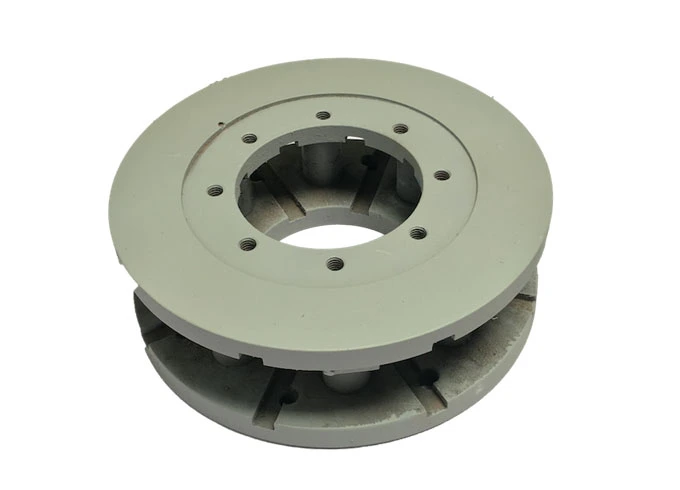

Features of Bare Wheel

Sturdy Foundation: The Bare Wheel provides a robust base, contributing to the overall stability of the blast wheel assembly.

Support for Components: It plays a crucial role in supporting other components, ensuring their proper function and efficiency.

Ensures Stability: Its solid construction ensures the stability of the entire assembly, enhancing the system’s reliability and performance.

For custom shot blasting machine spare parts, including shot blasting wheels, contact Rosterblast, your trusted shot blasting machine supplier, for a wide range of selections.

How to clean and polish bare wheel

Bare Wheel Cleaning:

Pre-Rinse: Blast off loose dirt and debris with a strong stream of water.

Bare Wheel Cleaner Selection: Choose a cleaner appropriate for your wheel material. Look for specific cleaners for chrome, steel, or other bare wheel types. Avoid harsh acidic cleaners.

Scrub Time: Employ a soft-bristled wheel brush to gently agitate the cleaner, reaching all nooks and crannies.

Rinse, Repeat: Rinse the wheels thoroughly with clean water to remove cleaner residue and loosened dirt. Repeat steps 2-4 if necessary for heavily soiled wheels.

Drying Duty: Use a clean, microfiber towel to meticulously dry the wheels. Trapped moisture can lead to water spots.

Bare Wheel Polishing (Optional):

Bare wheels don't always require polishing. However, if you desire a gleaming finish, proceed with caution depending on the material:

Aluminum: As mentioned earlier, use a metal polish formulated specifically for aluminum. Apply and buff following the steps mentioned previously.

Other Materials: Research polishes suitable for your specific wheel material (chrome, steel, etc.) to avoid damaging the finish.

Are steel bare wheels better than Aluminium bare wheels

Steel Bare Wheels:

Pros:

Durability: They're incredibly tough and can withstand a lot of abuse, bending rather than cracking under impact. Ideal for off-roading or harsh driving conditions.

Lower Cost: Generally less expensive than aluminum saw blade wheels.

Easier Repair: Bends in steel wheels can often be straightened by a professional, whereas cracked aluminum wheels might need replacing.

Heat Dissipation: Steel conducts heat better than aluminum, which can be beneficial for brakes, especially during heavy use.

Cons:

Weight: Steel wheels are significantly heavier than aluminum, which can reduce fuel efficiency and handling performance.

Susceptibility to Rust: Steel is prone to rust if not properly maintained. Regular cleaning and touch-up painting might be necessary.

Aesthetics: Steel wheels typically have a plain appearance compared to styled aluminum options.

Aluminum Bare Wheels:

Pros:

Lightweight: Significantly lighter than steel, which improves fuel efficiency and handling.

Aesthetics: Often available in various styles and finishes, enhancing the look of your vehicle.

Rust Resistance: Aluminum doesn't rust, eliminating a major maintenance concern.

Cons:

Durability: More susceptible to cracking or bending compared to steel, especially with impacts.

Cost: Generally more expensive than steel wheels.

Heat Dissipation: Aluminum doesn't dissipate heat as well as steel, which can be a factor during heavy braking.

Choose steel wheels if: Durability, lower cost, and off-road worthiness are your priorities. You're willing to put up with the heavier weight and potential for rust.

Choose aluminum wheels if: Lightweight design, stylish options, and rust resistance are more important. You're willing to pay a bit more and be mindful of potential impact damage or heat buildup during heavy braking.Ultimately, the best choice depends on your driving habits, priorities, and budget. Consider your typical driving conditions and what features matter most to you.

English

English