Key Features of Aluminum Cut Wire Shot

Lightweight

Ideal for applications where weight is a critical factor.

Non-Ferrous

Suitable for cleaning and deburring aluminum and non-ferrous parts.

Extended Lifespan

Boasts a longer life compared to traditional cast abrasives.

Surface Preservation

Minimizes wear and tear on finishing equipment.

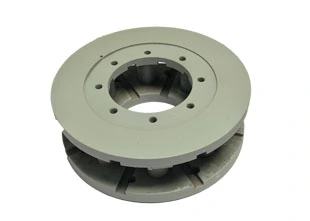

The Impact of Aluminum Cut Wire Shot on the Lifespan of Shot Blasting Machines

Aluminum cut wire shot can significantly impact the lifespan of shot blasting machines. Its uniform size and shape result in less wear and tear on the machine components, thereby extending their service life. Unlike other abrasive materials that can be irregular and cause damage, aluminum cut wire shot provides a consistent, smooth operation that minimizes mechanical stress.

Moreover, aluminum cut wire shot is less likely to become embedded in the machine parts, reducing the risk of rust and corrosion. This is particularly important in maintaining the efficiency and longevity of the machine.

Additionally, the recyclability of aluminum cut wire shot contributes to its cost-effectiveness. It can be reused multiple times without losing its effectiveness, reducing the need for frequent abrasive replacement and the associated machine downtime.

In conclusion, the use of aluminum cut wire shot can have a positive impact on the lifespan of shot blasting machines, leading to improved productivity and cost savings.

For custom blasting abrasive, contact Rosterblast for more selections.

Popular Sand Blasting and Shot Blasting Equipment

English

English