Shot Blasting Equipment in Automotive Industry

Automotive surface treatment and car paint prep

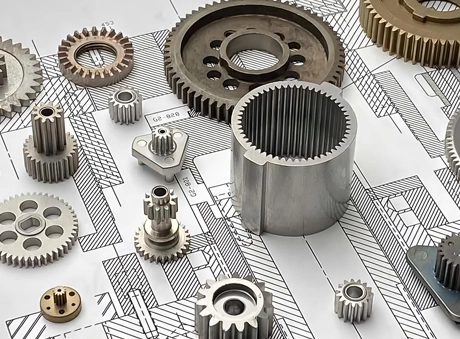

The automotive industry heavily depends on automotive shot blasting machines to maintain its rigorous quality standards. These automotive shot blasting machines are instrumental in guaranteeing flawless surface cleanliness, a critical aspect that directly influences the effectiveness of painting and coating procedures. The importance of these automotive paint prep machines cannot be overstated as they ensure the surfaces are free from rust, scale, and other contaminants, providing an ideal base for subsequent processes.

Applications: SShot blasting is utilized extensively in the auto paint prep sanding of a wide array of vehicle components. This includes car bodies, where it ensures a smooth and clean surface for automotive surface finishing and painting, chassis, where it helps in removing rust and old paint, and engine parts, where it aids in the removal of carbon deposits and other residues. The versatility of automotive shot blasting machine makes it an invaluable tool in the automotive manufacturing process.

Car shot blasting and auto paint prep effects

The impact of shot blasting on the production of automobiles is significant. Car shot blasting and auto paint prep facilitates improved paint adhesion, which not only enhances the aesthetic appeal of the vehicles but also adds to their longevity by providing a protective layer against environmental factors. Furthermore, Car shot blasting and auto paint prep reduce the risks of corrosion, a common issue in the automotive industry, thereby enhancing the overall product quality. Through these contributions, automotive shot blasting machine plays a pivotal role in the production of durable and visually appealing automobiles.

Automotive paint prep steps and process

Cleaning is a vital preparatory step in any car shot blasting and auto paint prep project. It sets the foundation for a flawless finish that not only looks great but also lasts longer. To begin, a thorough wash with appropriate car wash soap and warm water is crucial, ensuring dirt and grime are completely removed. Careful attention must be given to often overlooked areas like wheel wells and panel gaps.

Following cleaning, disassembly and masking come into play. Detaching parts like trim and door handles facilitates cleaning and prevents accidental paint application. For areas that can't be removed, meticulous masking with tape and paper ensures they remain untouched.

Auto paint prep sanding follows, utilizing a gradual grit progression to achieve a smooth surface for paint adhesion. Any necessary body repairs, such as addressing dents or rust spots, should be completed before moving on.

Optional stripping of old paint may be required for extensive restoration projects. Priming is then applied to provide a uniform base, promoting better paint adhesion.

Before automotive surface painting, a final cleaning ensures the surface is free of any contaminants that could affect the finish. This meticulous process guarantees a professional result that stands the test of time.

Types of Shot Blasting Machines for Automotive

h beam shot blasting machine, Rotary Barrel Shot Blasting Machine, cylinder shot blasting machine, Tumble Belt Shot Blasting Machine, Hanger Type Shot Blasting Machine, Overhead Rail Shot Blasting Machine

Types of Sand Blasting Machines for Automotive

Manual sandblasting machine, automatic sandblasting machine, rotary sandblasting machine, sand blasting room, sandblasting tank

For a custom automotive shot blasting machine with high quality and wide applications, contact Rosterblast, a shot blasting machine supplier.

English

English