When it comes to maintaining and operating an automatic shot blasting machine, having access to the right shot blasting machine spare parts is crucial. The blast nozzles, which are responsible for propelling the abrasive media towards the workpiece, are one of the key components that may require periodic replacement as they become worn over time.

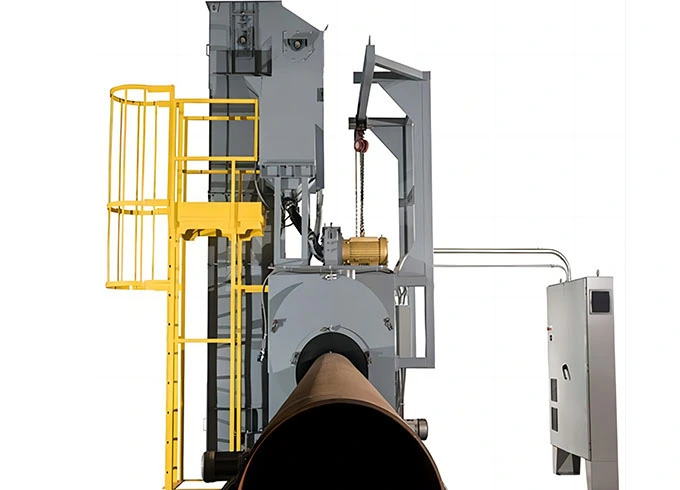

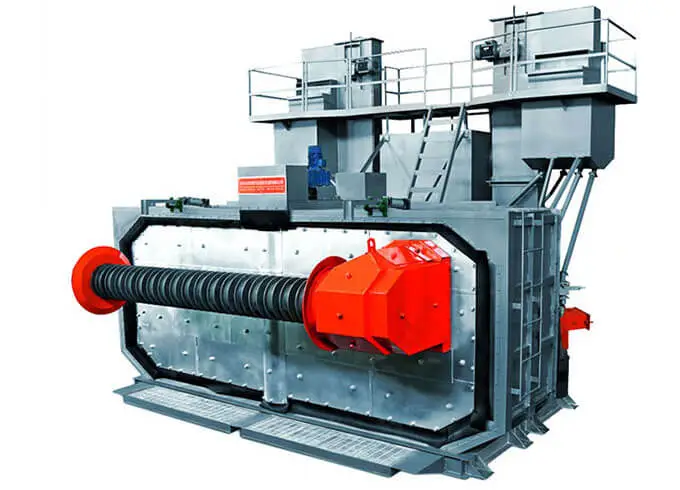

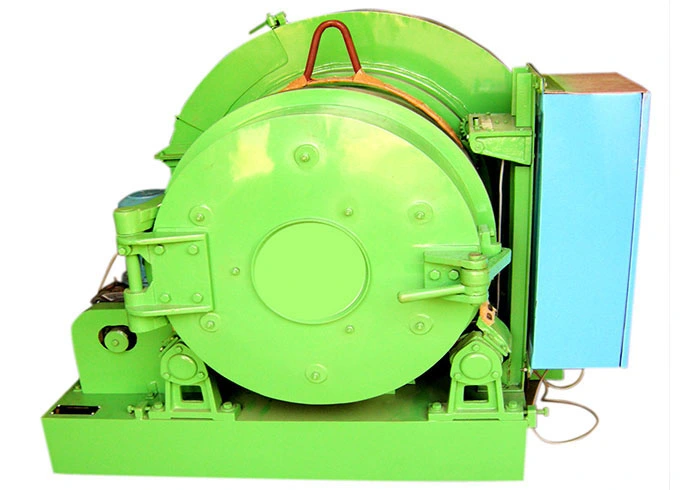

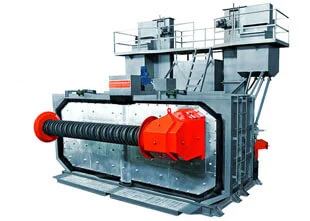

Another critical component is the blast wheel assembly, which is the heart of the shot blasting machine for sale, accelerating the abrasive media. Proper maintenance and occasional replacement of the blast wheel can help ensure the shot blasting machine's continued efficient operation. Additionally, the dust collection filters, which capture the dust and debris generated during the blasting process, will need to be replaced at regular intervals to maintain the system's effectiveness.

Beyond these core components, other spare parts that may require attention include seals, gaskets, and various control system electronics and electrical components. Maintaining an adequate stock of these replacement parts can help minimize downtime and keep the automatic shot blasting machine running smoothly.

Alongside the necessary spare parts, the choice of abrasive media is also a critical consideration for the effective operation of the shot blasting machine. Common abrasive media options include steel shot, glass beads, aluminum oxide, and ceramic shot, each with its own specific characteristics and suitability for different surface preparation requirements.

The selection of the appropriate abrasive media depends on factors such as the material, finish, and surface preparation needs of the workpieces being processed. Consulting with the shot blasting machine supplier or a shot blasting expert can help determine the optimal abrasive media for a given application, ensuring the best possible results.

Ensuring a reliable supply of high-quality abrasive media, in addition to maintaining a stock of critical spare parts, is essential for the continuous, efficient, and effective operation of an automatic shot blasting machine.

English

English