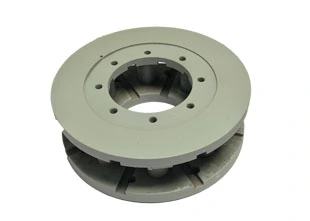

Key Features of Mesh Belt Shot Blasting Machine

Robust Durability

Demonstrates a longer lifespan than conventional cast abrasives.

Structural Integrity

Free from hollows, splits, or twins, ensuring structural consistency.

Shape Retention

Maintains size and form for extended periods, surpassing the longevity of cast abrasives.

Minimal Dust

Yields dust-free surfaces, enhancing workplace cleanliness.

For custom shot blasting machine spare parts, contact Rosterblast for more selections.

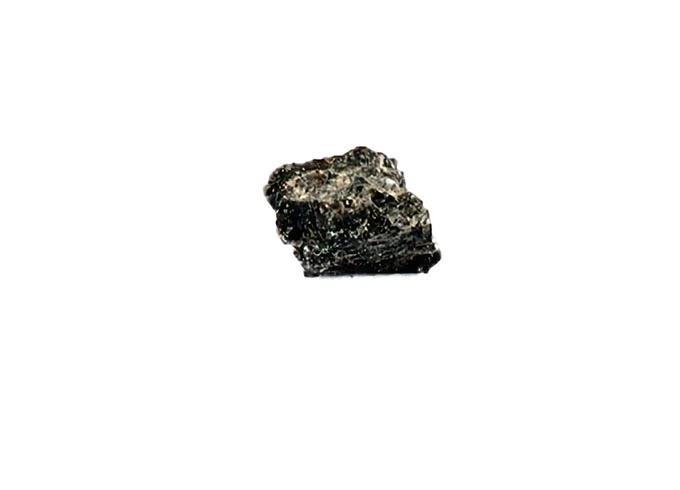

Steel grit blasting abrasive for shot blasting machines

Steel grit has emerged as a highly effective and commonly used abrasive material in shot blasting machines, renowned for its hardness, durability, and consistent performance across a wide range of applications.Steel grit is produced by crushing and processing steel scrap to create angular particles with sharp edges. This abrasive material is ideal for removing rust, scale, paint, and other contaminants from various metal surfaces.

H Beam Shot Blasting Machine: The sharp and angular profile of steel grit allows for thorough cleaning and preparation of the intricate surfaces of H beam shot blasting machine, ensuring a uniform finish.

Steel Plate Shot Blasting Machine: Steel grit's cutting action helps remove scale, rust, and other contaminants from steel plates, preparing them for subsequent coatings or further processing.

Hanger Type Shot Blasting Machine: The consistent flow and coverage of steel grit enable efficient and effective treatment of parts suspended on hangers, maximizing productivity.

Tumble Belt Shot Blasting Machine: The durability and longevity of steel grit make it well-suited for the tumbling action of these machines, reducing media replenishment requirements.

Mesh Belt Shot Blasting Machine: The angular shape of steel grit helps achieve the desired surface finish on parts moving through the mesh belt system.

Gas Cylinder Shot Blasting Machine: Steel grit's ability to reach tight spaces and corners ensures thorough cleaning and preparation of gas cylinders.

Steel Cylinder Shot Blasting Machine: The versatility of steel grit allows for effective treatment of steel cylinders, ensuring consistent and uniform results.

Steel Structure Shot Blasting Machine: The controlled cutting action of steel grit helps remove stubborn contaminants from complex steel structures, preparing them for painting or further fabrication.

Rotary Table Shot Blasting Machine: The reliable flow characteristics of steel grit enable consistent coverage and treatment of parts rotating on the table.

Floor Shot Blaster: Steel grit's durability and long lifespan make it a suitable choice for high-volume floor shot blasting applications.

Preservation Lines: The sharp edges of steel grit help remove rust and scale from metal surfaces, preparing them for preservation coatings.

Pipe Shot Blasting Machine: The angular profile of steel grit ensures thorough cleaning and preparation of the interior and exterior surfaces of pipes.

Overhead Rail Shot Blasting Machine: The consistent performance of steel grit allows for effective treatment of parts suspended on overhead rails.

Wire rod shot blasting machine: Steel grit's ability to reach and clean the intricate surfaces of wire rods helps maintain product quality.

Rotary Barrel Shot Blasting Machine: The durability and controlled cutting action of steel grit make it a reliable choice for tumbling and cleaning parts in rotary drum shot blasting machine.

Shot Peening Machine: The carefully controlled size and shape of steel grit enable precise shot peening results, improving the fatigue life of components.

By leveraging the versatility and performance of steel grit blasting abrasive, manufacturers can optimize the efficiency, consistency, and quality of their shot blasting operations across a diverse range of machine configurations.

Steel grit blasting abrasive for shot blast booths

Steel grit is a highly effective abrasive media that has become a popular choice for shot blasting applications, particularly in the context of industrial blast rooms.

By selecting the right steel grit blasting abrasive for their specific shot blast booth requirements, shot blasting machine supplier can optimize the performance, efficiency, and consistency of their surface preparation and treatment processes. The versatility and effectiveness of steel grit make it a valuable asset in the diverse world of shot blasting technology.

Why Choose Roster steel grit supplier

When it comes to selecting a steel grit supplier for shot blasting applications, Roster stainless steel shot blasting stands out as a reliable and reputable choice.

Quality Assurance: Roster employs stringent quality control measures throughout their manufacturing process, ensuring the steel grit they supply meets the most stringent industry standards. This commitment to quality assures customers of consistent performance and reliable results.

Precise Grading and Sizing: Roster's steel grit is meticulously graded and sized to provide the optimal particle distribution for various shot blasting applications. This attention to detail allows customers to achieve the desired surface finish and treatment consistency.

Customized Solutions: Roster's team of experts works closely with customers to understand their unique requirements and provides customized steel grit solutions. This level of responsiveness and flexibility helps optimize the performance of shot blasting machines and processes.

Extensive Product Range: Roster offers a comprehensive range of steel grit products, catering to the diverse needs of shot blasting applications, from H-beams and steel plates to gas cylinders and wire rods. This wide product portfolio ensures customers can find the right solution for their specific requirements.

Reliable Supply and Logistics: Roster's robust supply chain and logistical capabilities ensure a consistent and timely delivery of steel grit to customers, minimizing downtime and maintaining productivity in their shot blasting operations.

Technical Support and Expertise: Roster's team of technical experts provides valuable guidance and support to customers, helping them optimize the selection, usage, and maintenance of steel grit for their shot blasting machines. This level of technical expertise is invaluable in maximizing the performance and efficiency of shot blasting processes.

By partnering with Roster, manufacturers can leverage the company's quality, precision, customization, and technical expertise to enhance the performance and efficiency of their shot blasting operations. Roster's reputation as a reliable and innovative steel grit supplier makes them a trusted choice in the industry.

English

English