Shot Blasting Equipment in Foundries and Metal Casting

Introduction: Foundries heavily depend on shot blasting machines to guarantee the production of high-quality metal castings. Shot blasting is the preferred solution for cleaning and descaling castings, a process that directly influences the quality of the final products. The importance of these machines in foundries cannot be overstated as they ensure the surfaces are free from sand, scale, and other contaminants, providing an ideal base for subsequent processes.

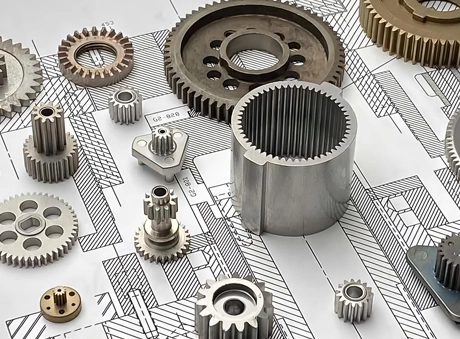

Applications: Shot blasting is utilized extensively in the foundry industry. It is employed in cleaning sand and scale from metal castings, ensuring they meet industry standards. This includes a wide array of castings, from small components to large machinery parts. The versatility of shot blasting makes it an invaluable tool in the foundry manufacturing process.

Effects: The use of shot blasting in the foundry industry has significant effects. It results in improved casting quality by ensuring that all components are clean and free from potential failure points like sand or scale. It also reduces the risks of defects, a common issue in the foundry industry, thereby enhancing the overall product quality. Furthermore, it contributes to cost-effective production by reducing the need for manual cleaning and rework. These factors are crucial in foundry operations, making shot blasting an essential process in the industry.

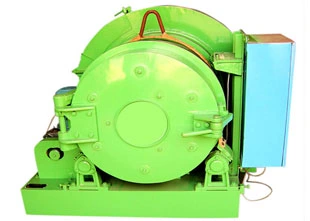

Types of Shot Blasting Machines for Foundries and Metal Casting

h beam shot blasting machine, Gas Cylinder Shot Blasting Machine, Hanger Type Shot Blasting Machine, Rotary Barrel Shot Blasting Machine

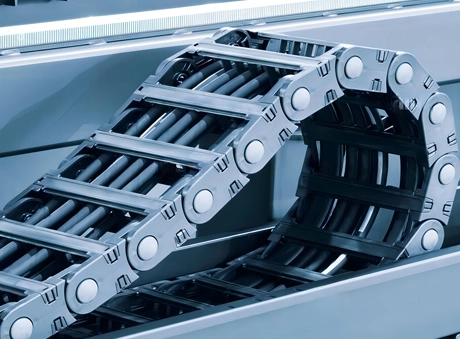

Types of Sand Blasting Machines for Foundries and Metal Casting

Casting sand blasting machine, casting mold surface sand blasting machine, sand blasting tank.

Popular Sand Blasting and Shot Blasting Equipment

English

English