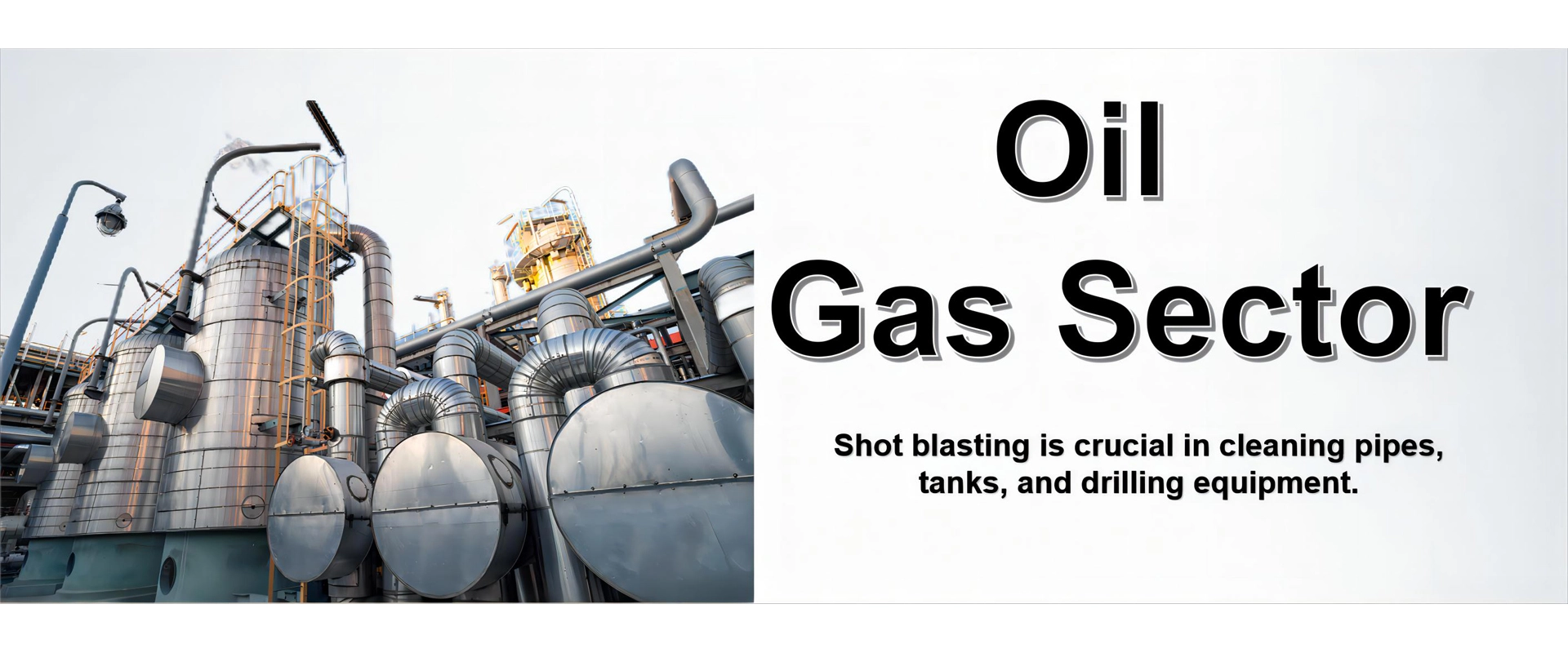

Shot Blasting Equipment in Oil & Gas Industry

Introduction: The oil and gas industry operates in some of the most extreme environments on earth, from the scorching deserts to the icy Arctic. This makes the reliability of equipment a critical factor in maintaining operational efficiency and safety. Shot blasting, a process that involves propelling abrasive material under high pressure to clean and prepare surfaces, is widely used in this industry. It helps to ensure that equipment exposed to these harsh conditions remains reliable and safe to use.

Applications: Shot blasting plays a pivotal role in the maintenance and preparation of various equipment in the oil and gas industry. It is commonly used to clean pipes that transport oil and gas, tanks that store these resources, and drilling equipment that penetrates the earth’s crust. By removing rust, scale, and other contaminants, shot blasting ensures these components function optimally.

Effects: The benefits of shot blasting in the oil and gas industry are manifold. Firstly, it significantly reduces corrosion, a common issue in this industry due to the harsh environments and corrosive substances involved. By removing surface contaminants and providing a clean, rough surface for coatings to adhere to, shot blasting improves the performance of equipment. Furthermore, it extends the service life of equipment, reducing the need for frequent replacements. This is particularly important in an industry where equipment reliability can significantly impact operational efficiency and safety.

Types of Shot Blasting Machines for Oil and Gas

h beam shot blasting machine, Gas Cylinder Shot Blasting Machine, cylinder shot blasting machine , Floor Shot Blaster, Tumble Belt Shot Blasting Machine, Hanger Type Shot Blasting Machine

Types of Sand Blasting Machines for Oil and Gas

Pipe inner wall sandblasting machine, drilling equipment sandblasting machine, sand blasting room

English

English