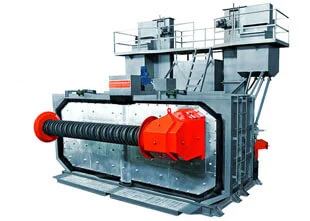

In industries where steel structures play a crucial role, ensuring their quality and durability is paramount. This is where the H beam shot blasting machine steps in, offering a comprehensive solution to clean and prepare steel surfaces for various applications. Let's delve deeper into what makes this machine indispensable in the manufacturing world.

Exploring the H Beam Shot Blasting Machine

The h beam shot blasting machine stands out for several key reasons. Firstly, it prioritizes safety with its robust design and reliable safety protection devices. During maintenance or lubrication procedures, these safety measures ensure the well-being of personnel inside the cleaning chamber, highlighting its commitment to operational safety.

Moreover, many users integrate shot blasting machines into their production lines, emphasizing the need for seamless integration and operational efficiency. Intelligent operation is crucial to minimize manual labor costs and optimize productivity. Without smart operation, the risk of increased operational expenses looms large.

Key Features and Functionality

When examining the functionality of the h beam shot blasting machine, attention to detail is essential. For instance, excessive wind force in the separator can impede the precise separation of abrasive particles, leading to wastage. Adjusting the airflow to an optimal level resolves this issue, ensuring efficient usage of abrasive materials.

In shipyards, where steel plates susceptible to rust are commonplace, shot blasting machines emerge as saviors. By eliminating rust from machinery surfaces, these machines uphold the quality standards crucial for shipbuilding endeavors.

Principles of Operation

Understanding the operational principles sheds light on the versatility of h beam shot blasting machines. They employ various cleaning agents tailored to specific requirements, ranging from mild alkaline solutions to neutral cleansers devoid of water, diesel, or kerosene.

The high-speed impact of steel or iron shots on component surfaces induces lattice distortion, enhancing surface hardness—a fundamental aspect of surface cleaning and strengthening. Shot blasting finds extensive use in cleaning castings and fortifying component surfaces against wear and tear.

Additional Insights

Beyond surface cleaning, h beam shot blasting machines serve diverse purposes. Over time, components may darken or rust, necessitating maintenance and cleaning procedures facilitated by automatic shot blasting machine. Specialized sensors ensure precision by activating the blasting process only when components enter the projection area, mitigating material wastage and enhancing operational efficiency.

Moreover, shot blasting machines leverage high-speed rotating projectiles to cut through contaminants and oxides on shelf surfaces without compromising structural integrity—a testament to their effectiveness and versatility.

In conclusion, the h beam shot blasting machine isn't merely a piece of equipment; it's a cornerstone of efficiency and quality in steel fabrication and maintenance. By adhering to stringent safety standards, optimizing operational workflows, and embracing technological advancements, these machines continue to redefine industry standards, ensuring the longevity and reliability of steel structures worldwide.

As a professional steel grit manufacturer, Roster offers a wide range of top-quality surface treatment equipment for various applications. Popular products provided by Roster are as follows:

Preservation Lines

Sand Blasting Booth for Sale

Tumble Belt Shot Blasting Machine

Wire Rod Shot Blasting Machine

Gas Cylinder Shot Blasting Machine

Steel Pipe Shot Blasting Machine

Shot Blasted Stainless Steel

Feed Spout

Rolling Drum Shot Blasting Machine

Sandblasting Machine for Sale

Control Cage

Table Type Shot Blasting Machine

Cylinder Shot Blasting Machine

English

English