Abrasive blast cleaning is a widely used industrial cleaning method that involves propelling abrasive materials at high speeds to remove surface layers and reveal a clean substrate. Over the years, this technique has evolved, leading to specialized methods like shot blasting and sandblasting. While both are effective, they differ in their mechanisms and applications. This article explores the distinctions between the two and their respective benefits.

What is Shot Blasting?

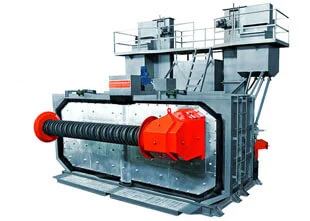

Shot blasting uses centrifugal or mechanical force, often generated by a rotating turbine wheel, to propel abrasive materials at a surface. The abrasives can vary depending on the project, with steel being the most common. Other materials like glass, plastic, or aluminum oxide may also be used. Shot blasting is particularly effective for cleaning steel and other ferrous metals, making it a go-to solution for heavy-duty applications.

What is Sandblasting?

Originally, sandblasting relied solely on sand as the abrasive, but this method faced challenges due to sand's moisture content and potential contaminants. Modern sandblasting now uses alternative abrasives, such as fine or recycled glass, for more precise and effective results. Unlike shot blasting, sandblasting relies on compressed air to propel the abrasives. This method is ideal for softer or more sensitive materials, as it not only cleans but also enhances the surface's mechanical profile, making it easier to apply paint or coatings.

Key Differences Between Sandblasting and Shot Blasting

The primary difference lies in the propulsion mechanism: shot blasting uses centrifugal or mechanical force, while sandblasting uses compressed air. This distinction influences their applications and effectiveness for different materials.

Neither method is inherently superior; the choice depends on the specific requirements of the project. Here are the key benefits of each:

Sandblasting:

Less forceful and less invasive, reducing the risk of damage.

Typically more cost-effective.

Offers greater flexibility in applications.

Improves the surface's mechanical profile, aiding in painting or coating adhesion.

Shot Blasting:

More effective for tougher materials like steel.

Environmentally friendly, producing minimal byproducts and avoiding harmful chemicals.

Excellent for removing rust and corrosion.

In conclusion, both shot blasting and sandblasting have unique advantages. The decision between the two should be based on the material being treated and the desired outcome.

English

English