The aerospace industry is one that demands precision, durability, and high performance. One of the critical processes that contribute to these requirements is surface treatment. Surface treatment applications in aerospace play a vital role in enhancing the performance and longevity of various components. This article will delve into the importance of surface treatment applications in the aerospace industry.

Enhancing Durability and Resistance

Aerospace components are subjected to extreme conditions, including high temperatures, pressure, and corrosive environments. Aerospace surface treatment processes, such as shot peening, help enhance the durability and resistance of these components. By inducing compressive stress on the surface, shot peening increases resistance to fatigue, stress corrosion, and cracking, thereby extending the component’s lifespan.

Improving Adhesion

Surface treatment applications also play a crucial role in improving adhesion for bonding and coating processes. Aerospace surface finishing processes, such as anodizing or chromate conversion, prepare the surface for subsequent coating by creating a rough surface topography. This enhances the adhesion of paints, primers, and sealants, ensuring they stay intact even under harsh conditions.

Reducing Friction and Wear

In the aerospace industry, reducing friction and wear is critical to ensure the smooth operation of moving parts and minimize maintenance needs. Surface treatment applications, such as hard anodizing or dry film lubrication, provide a hard, low-friction surface that reduces wear and tear, thereby enhancing the efficiency and reliability of aerospace components.

Ensuring Compliance with Industry Standards

The aerospace industry is governed by stringent standards and regulations to ensure safety and performance. Surface treatment applications help aerospace manufacturers comply with these standards. For instance, certain surface treatments can help meet corrosion resistance standards, while others can help achieve the required surface finish or hardness.

Enhancing Aesthetics

While performance and durability are paramount in the aerospace industry, aesthetics also matter, especially in commercial aviation. Surface treatment applications can enhance the visual appeal of aerospace components through processes like polishing, painting, or anodizing, which can provide a range of colors and finishes.

In conclusion, surface treatment applications play a vital role in the aerospace industry, enhancing durability, improving adhesion, reducing friction and wear, ensuring compliance with industry standards, and enhancing aesthetics. As a leading provider of aerospace surface treatment solutions, Roster shot blasting machine supplier is committed to delivering high-quality, efficient, and reliable solutions to meet the demanding needs of the aerospace industry.

As a professional steel grit manufacturer, Roster offers a wide range of top-quality surface treatment equipment for various applications. Popular products provided by Roster are as follows:

Preservation Lines

Beam Shot Blasting Machine

Sand Blasting Booth for Sale

Tumble Belt Shot Blasting Machine

Wire Rod Shot Blasting Machine

Gas Cylinder Shot Blasting Machine

Steel Pipe Shot Blasting Machine

Shot Blasted Stainless Steel

Feed Spout

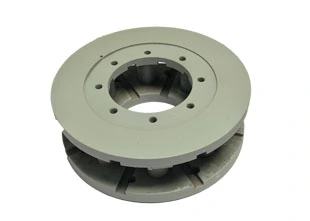

Rolling Drum Shot Blasting Machine

Sandblasting Machine for Sale

Control Cage

Table Type Shot Blasting Machine

Cylinder Shot Blasting Machine

English

English